Our labels are available in multiple film materials and finishes designed for professional product packaging and indoor use.

Materials & Lamination

- Materials: White BOPP (Biaxially Oriented Polypropylene), Clear BOPP, Hologram (BOPP)

- Lamination options: Glossy or matte laminate

- Durability: Durability: Water- and oil-resistant for everyday handling; not designed for outdoor application

- UV exposure: Indoor use recommended; avoid prolonged direct sunlight

- Adhesive: Permanent acrylic adhesive; temperature tolerance –65°F to 200°F (after application)

Backing & Format Notes

All labels are finished on rolls for efficient application.

- Paper backing: Best for hand application and short runs

- PET backing: Available for Glossy and Matte White BOPP Laminated Labels only; optimized for machine and high-speed application

- Clear labels: Finished on a glassine liner to maintain transparency

Sizes & Minimums

Minimum label size:

- 0.5" × 0.5" for most paper and film labels

- 2" × 2" minimum when using PET backing

Maximum size: 11" × 14"

Minimum order: 125 labels

Production & Turnaround

- Standard turnaround: 2–5 business days after proof approval for most materials

- Rush Printing: Need it fast? Upgrade to Rush Printing and we will print your order within 1 business day after proof approval. Learn more about Rush Printing

- Shipping speed: Selected separately at checkout

Laminated Labels are designed for product packaging and labeling using durable film materials. Available in multiple finishes and backing options, they’re made for indoor-use products that need a polished, professional look with water- and oil-resistant durability. All labels are finished on rolls for efficient hand or machine application.

Ideal for

- Product packaging and labeling

- Bottles, jars, cans, boxes, and containers

- Food, beverage, cosmetics, personal care, and wellness products

- Retail and ecommerce packaging

- Compliance information, ingredients, instructions, and barcodes

- High-volume labeling workflows

Choosing the Right Label Type

- Glossy Labels: Best for bold designs, photography, and vibrant colors when shine and shelf impact matter more than glare reduction.

- Matte Labels: Best for text-heavy designs and readability. The non-glare finish supports writing with a permanent marker.

- Clear Labels: Creates a clean, “no-label” look by letting your packaging show through.

- Holographic Labels: Adds an iridescent, light-reactive effect for high-impact or promotional packaging.

Application & Backing Options

All labels are finished on rolls for efficient application.

- Hand applying: Choose Paper Backing

- Machine applying: Choose PET Backing (available for Glossy and Matte White BOPP Laminated Labels only)

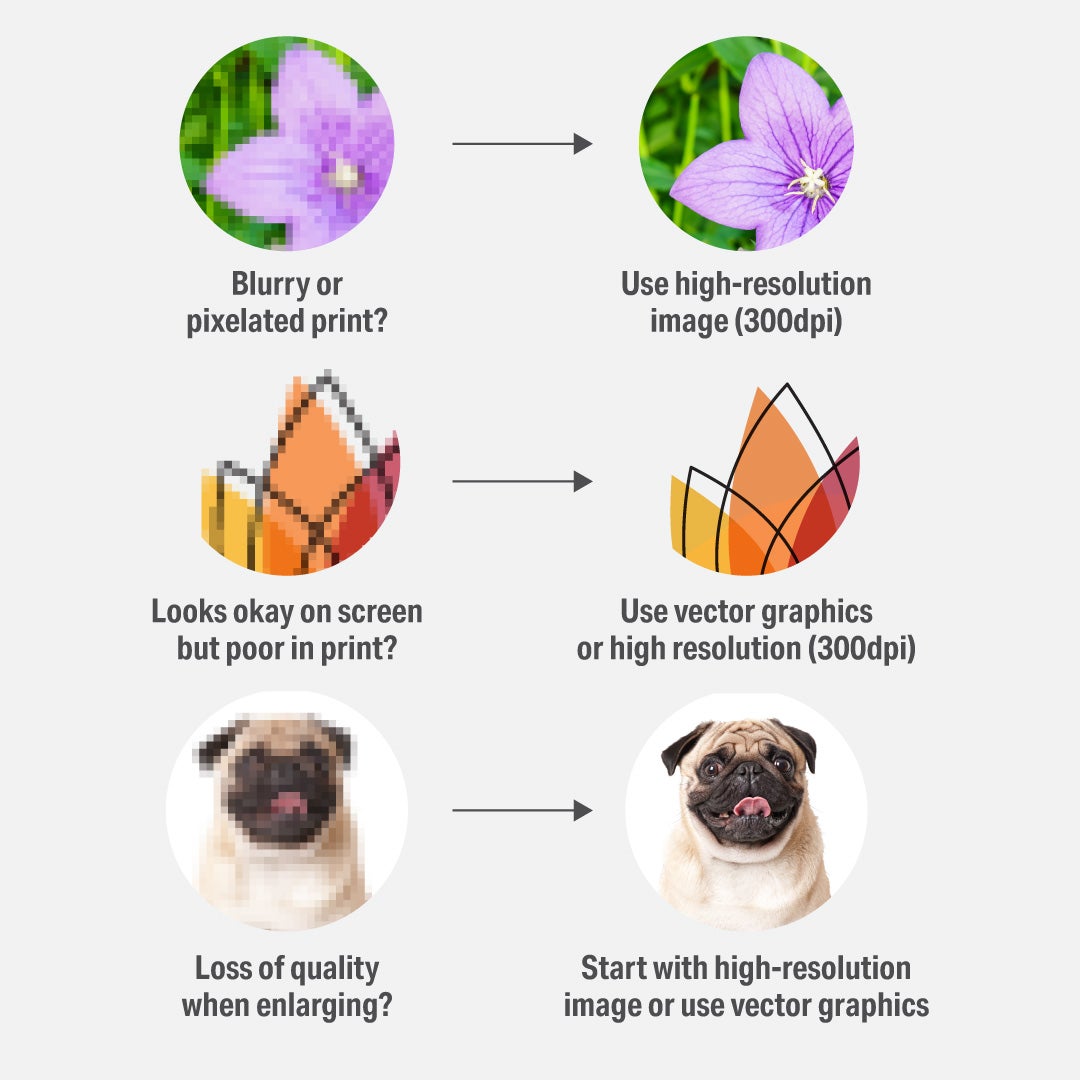

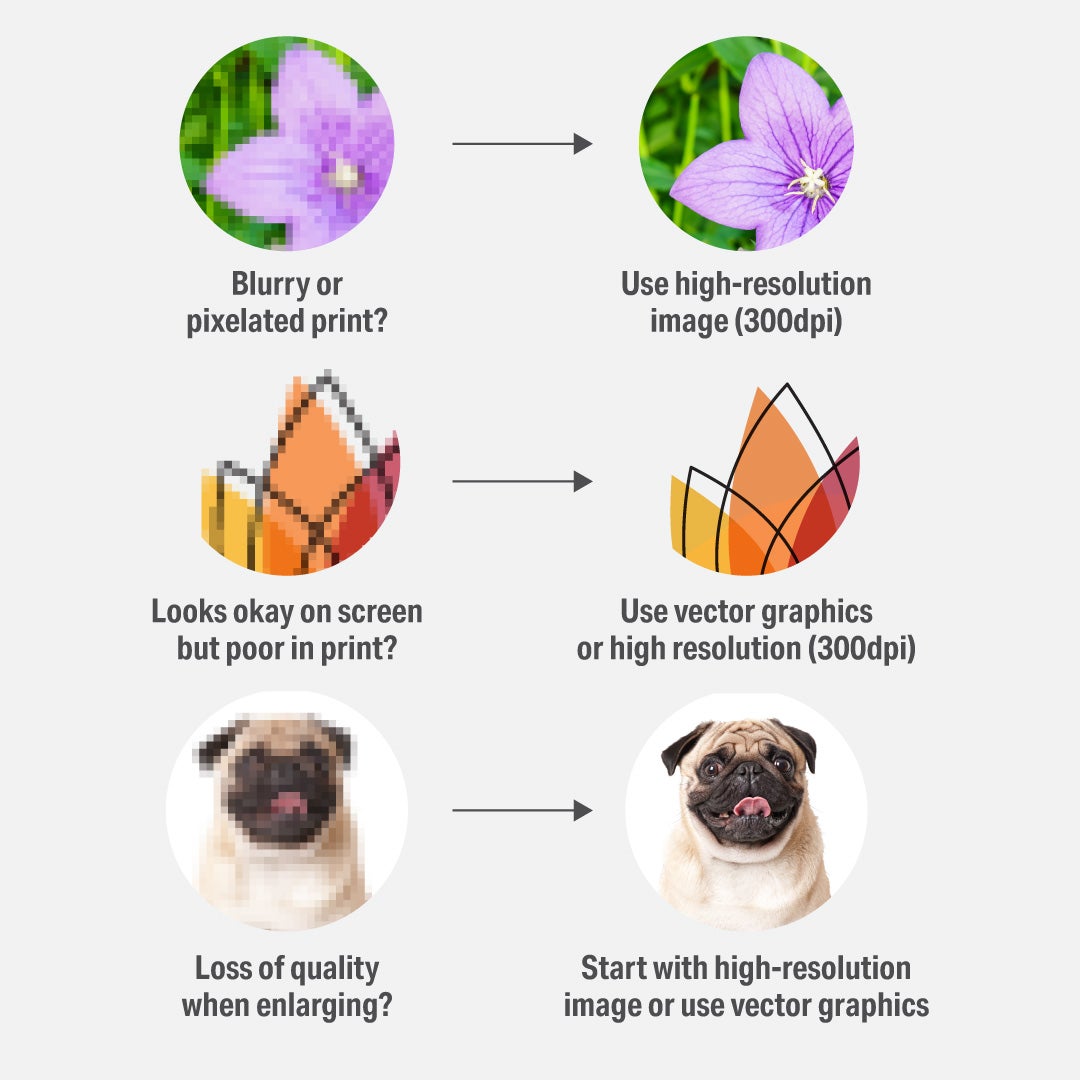

Most print issues come from artwork setup. Getting these details right helps ensure clean cuts, accurate color, and smooth production.

Need help or not sure your file is ready? Check out our Artwork Setup Guidelines.

Artwork Essentials

- Resolution: 300 DPI at final size

- Color Mode: CMYK (convert Pantone colors to CMYK)

- Preferred Files: Vector PDF or AI

- Accepted Formats: PDF, AI, PSD, JPG, PNG, TIFF, EPS

Design Safety Tips

- Keep text and important elements at least 1/16" inside the cutline

- Add 1/8" bleed for edge-to-edge color

- Wrap labels: Add 0.25" overlap for cylindrical containers (bottles, jars, tubes)

- Outline fonts and embed images

Material-specific notes

Some materials and formats have unique artwork setup requirements. For detailed guidance, review the appropriate setup guide below:

Proofing Process

- Every file is reviewed by our in-house Art Team before printing to help ensure it’s production-ready.

- You’ll receive a free digital proof to review and approve before printing begins. See what’s included in your proof.

Frequently Asked Questions

- PET backing (Glossy & Matte White BOPP only): Durable plastic liner for machine application and high-speed dispensing; recommended for labels 2" or larger.

- Paper backing: Flexible liner that’s easier to peel and best suited for hand application

- 1 inch (about the size of a quarter): Small containers or subtle branding

- 2 inches (about the size of an Oreo): Jars, bottles, and everyday product packaging

- 2 × 3.5 inch (business card size): Front or back labels for larger packaging

What are Laminated Labels?

Laminated Labels are custom-printed product labels made from BOPP (biaxially oriented polypropylene) film and finished with a protective laminate. Available in Glossy, Matte, Clear, and Holographic, they’re designed for professional, indoor-use packaging and everyday handling.

What’s the difference between Glossy, Matte, Clear, and Holographic labels?

Glossy Labels: Shiny, reflective finish that enhances color vibrancy and visual impact

Matte Labels: Smooth, low-glare finish that improves readability

Clear Labels: Transparent film that allows packaging to show through

Holographic Labels: Iridescent finish that shifts in the light for added visual interest

Can I write on Laminated Labels?

Matte Labels: Yes. Permanent marker recommended

Glossy, Clear, and Holographic Labels: Not recommended, as ink may smudge or resist adhesion

What is the difference between PET backing and paper backing?

The difference is how the labels are applied.

What’s the difference between Laminated Labels and Paper Labels?

Laminated Labels are printed on BOPP film and finished with a laminate. They’re water- and oil-resistant and designed for frequent handling and moisture-prone environments.

Paper Labels are printed on paper-based materials (Glossy Paper, Matte Recycled, or Kraft) and finished with a UV varnish. They’re best for dry, indoor use and provide a natural, writable surface.

In short: Choose Laminated Labels for durability and moisture resistance. Choose Paper Labels for dry, indoor applications where a paper look and feel matters.

What size should my label be?

StickerGiant offers custom label sizes from 0.5" × 0.5" to 11" × 14", so the best size depends on your product and where the label will be applied.

Common size references:

If you’re unsure, cut a piece of paper to size and place it on your product where the label will be applied. You’ll always receive a proof to confirm sizing before printing.

Need help deciding, check out our "What Size Should My Sticker or Label Be" guide.

Are Laminated Labels water resistant?

Laminated labels are water resistant and resist oil and everyday surface wear. They perform well with brief moisture exposure but are not designed for long-term submersion or prolonged outdoor use.

Need more detail? Read our full explanation of water resistant vs waterproof.

Are Laminated Labels dishwasher safe?

Laminated Labels are water resistant and durable, but not dishwasher safe. Repeated dishwasher cycles can affect the laminate over time. For best results, we recommend hand washing.

Can I get my labels fast?

Yes. Most orders print in 2–5 business days after proof approval. If you need your labels sooner, Rush Printing is available on most products and prints within 1 business day after proof approval.

Rush Printing affects production time only. Shipping speed is selected separately at checkout, and availability depends on production capacity.

What does “Next Day Air” shipping mean?

Next Day Air speeds up shipping time only, not production time. Your order must finish printing before it ships. Once shipped, Next Day Air delivers your package the next business day.

How do I check my order status?

Visit our Order Status page and enter your order or item number to see updates from proofing through shipping. We’ll reach out if any action is needed from you.